Recycle-ready Vacuum Brick Pack for Ground Coffee

Introduction:

At Taghleef Industries, we are committed to developing innovative and sustainable packaging solutions. In this case study, we explore how we can reDESIGN™ a solution that effectively replaces a hard-to-recycle structure for ground coffee vacuum brick packs. This shift not only promotes better recyclability but also delivers unbeatable protection and performance.

Challenge:

The coffee industry traditionally relies on multi-material packaging for vacuum brick packs, often combining materials like aluminum, PET, and PE. While these solutions offer good barrier properties, they pose significant challenges such as complexity in recycling.

Solution:

Taghleef Industries’ proposed solution offers a sustainable alternative for ground coffee vacuum brick packs.

- Material composition: Our solution offers better recyclability compared to the traditional multi-material structure.

- Exceptional barrier properties: Our EXTENDO® high barrier film offers excellent barrier properties against moisture, oxygen, and aroma, ensuring the freshness and quality of ground coffee throughout its shelf life.

- Exceptional Performance: The overall structure offers superior heat resistance and machinability, making it ideal for various packaging processes and ensuring consistent product quality.

| Traditional Structure | Ti’s Solution |

| PET 12 µm + Alu 8 µm + PE 60 µm | TTR 18 µm + EXTENDO® XZMX 18 µm + PE 60 µm |

Results:

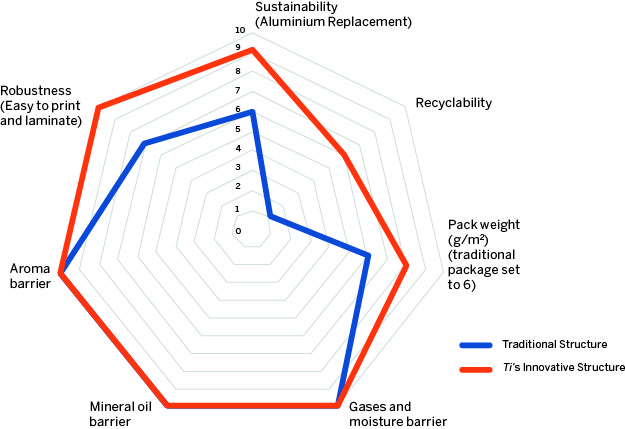

The implementation of Taghleef Industries’ reDESIGN™ proposal for ground coffee vacuum brick packs has resulted in several key benefits:

- Simplified recycling: The structure allows for easy and efficient recycling through existing polyolefin recycling streams, contributing to a more circular economy.

- Guaranteed product protection: The superior barrier properties of our EXTENDO® films safeguard coffee freshness and aroma, leading to a higher quality product for consumers.

- Improved performance: The proposed solution demonstrates better robustness, leading to increased efficiency in the converting process.

Conclusion:

Taghleef Industries’ solution shows a successful shift towards sustainable packaging in the coffee industry. This innovative solution not only addresses environmental concerns but also delivers exceptional performance and product protection, making it a compelling choice for coffee roasters and consumers alike.