Innovative Flow Wrap Packaging Solutions for your Biscuit and Bakery Items

Flow wrap packaging is a fast and efficient way to package various products. It is commonly used for food products such as candy, cookies, chips, and snacks. With the various packaging features such applications demand, Taghleef has developed assorted solutions that can cater to an array of needs:

High-performing Coated films for Improved Machinability

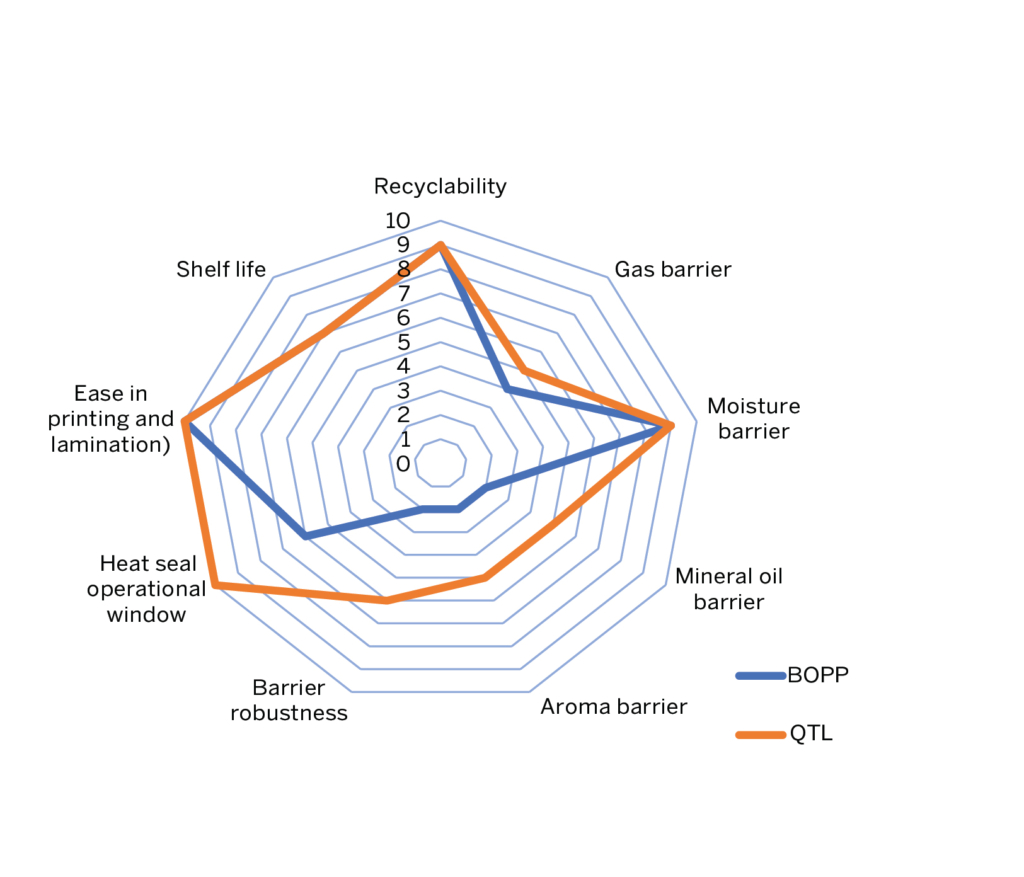

Coated BOPP films are famous for flow wrap packaging applications because they offer several advantages. One of Ti’s Coated film offerings, QTL, provides several benefits for your packaging, including:

- Excellent machinability: Taghleef’s QTL is easy to run on flow wrap machines, which can help to improve production efficiency and reduce downtime.

- Superior barrier properties: It can also provide better barrier protection against moisture, oxygen, and other gases, which can help to extend the shelf life of products.

- Versatility: QTL film suits various products, including wafers, biscuits, and other bakery items.

| Previous Structure | Ti’s New Proposal |

| TSS 30 µm | QTL 25µm |

Recyclable PVDC Alternative with High Transparency

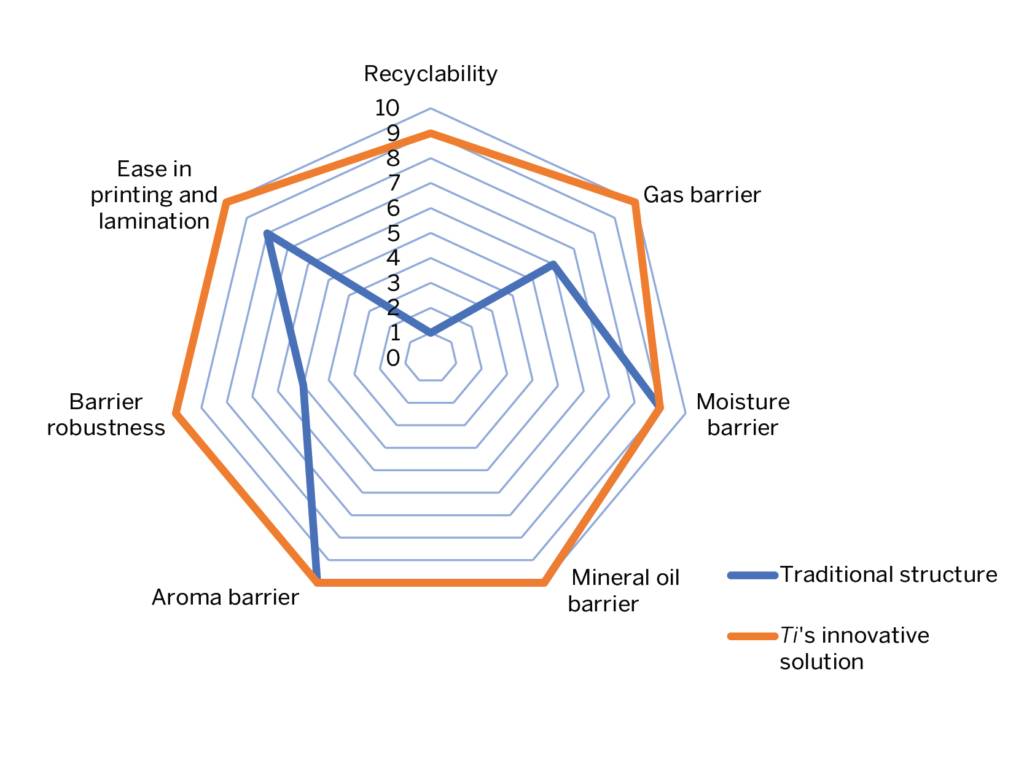

To answer our customers’ sustainability requirements, one of Ti’s successful developments is an excellent PVdC and Polyamide replacement. Through Taghleef’s reDESIGN™ approach, a fully PP-based alternative for a Tortilla wrap application has been launched in the market.

With this new proposal, Ti’s EXTENDO® XTMU offer the following advantages:

- Excellent transparency: EXTENDO® XTMU is a highly transparent film with a clear and glossy appearance on the shelf.

- Better recyclability: This fully PP-based structure makes recycling the packaging easier than the previous multi-material structure based on PVDC/ PA and PE.

- Ultra high oxygen barrier: EXTENDO® XTMU boasts a better-performing oxygen barrier and barrier robustness than traditional structures. This keeps the food item fresher for longer, thereby minimising food waste.

| Previous Structure | Ti’s New Proposal |

| PVdC coated PET/PE 50 µm PA/PE | EXTENDO® XTMU 20 µm + Cast PP 25 µm |

Ti’s redesigned structure meets the criteria for ideal packaging for bakery items – performance, protection and sustainability.